Unleashing Industrial Manufacturers from the Grip of Data Silos: The Asset-Centric Revolution

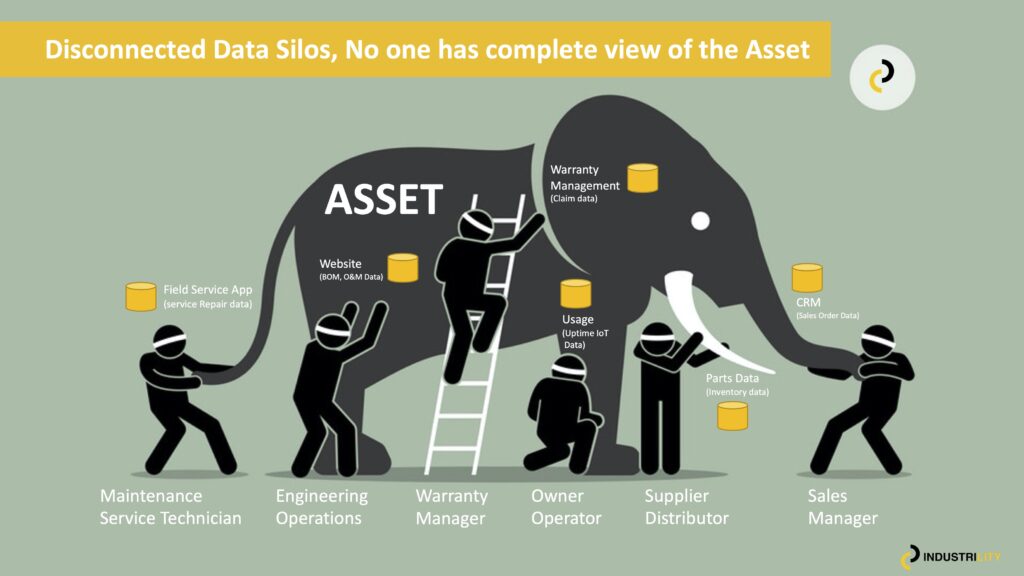

In every industry, including Industrial Manufacturing, data is the lifeblood that fuels growth and innovation. However, a relentless plague haunts this particular sector: data and app silos. Much like the fabled tale of the blind men and the elephant, manufacturers are groping in the dark, unable to perceive the complete reality of their equipment (“assets”). In this blog post, we’ll dive into the damaging effects of data and app silos on industrial manufacturers, and present an asset-centric solution. We call it the “Operational Digital Twin”.

The Six Blind Men and the Elephant

The story of the six blind men and the elephant serves as a fitting analogy for the challenge of data and app silos. In the tale, each blind man touches a different part of an elephant and forms his own perception of the animal based on his limited experience. One believes the elephant is like a wall (touching the side), while another thinks it’s like a spear (touching the tusk), and so on. None of them can grasp the complete reality of the elephant because they are limited by their isolated experiences.

Likewise, in the industrial manufacturers market, data and app silos create isolated pockets of information about the asset. Each department, team, or piece of equipment within an organization generates its own data and relies on its specific applications. Consequently, decision-makers are left with fragmented, incomplete information. Engineering, operations, warranty, maintenance, and management teams may have different perspectives on the same asset, resulting in disjointed decision-making, reduced efficiency, and missed opportunities for optimization.

The Data Silo Plague

Industrial Manufacturers have variety of tools today. ERP, PLM, CRM, IoT, FSM, APM, EAM, BIM, CAD, CAM, XLS, CSV, FTP, CPQ and the TLA (Three-Letter Acronym) list goes on. Each tools forms a partial understanding, but none grasps the complete picture of the asset (magnificent elephant) and it results in:

- Inefficiency: Silos hinder effective communication and collaboration across different departments, leading to redundant efforts, duplicated data, and increased operational costs and often access nightmare.

- Poor User Experience: Every user (including the customer/owner/operator) has to login in at least 20 different systems to get info about simple things like parts identification, warranty contract/claims, service history, commissioning and startup manuals/reports, parts BOM and pricing, dimensions and diagrams. The user experience suffers!

- Limited Insights: Without a unified view of data about the asset, organizations struggle to gain comprehensive insights into their operations. This restricts the ability to identify patterns across equipment models, make informed decisions about their installed base, and drive continuous improvement.

- Missed Opportunities: Because the sales (CRM) team does not know about operations and service (FSM) team, manufacturers often miss an opportunity for selling new equipment or parts and service at the right time. Only because of these two data silos, which had two different perspectives (Sales view and PM view), it lost an opportunity to help their customer in process optimization, cost reduction, and enhanced performance.

- Slow Response Times: When a new part is desired by a customer because of routine maintenance, or repair, it often phone calls, emails, faxes, sending excel sheets versions and lot of back and forth to just find out “Right part for my installed equipment”. This is because the as-built BOM (PLM) of equipment was not accessible to the sales or service team. Siloed data and apps impede agility and responsiveness, hindering organizations from adapting swiftly to changing market conditions.

‘The Whole (Asset) is Greater than the Sum of its Parts’ and none of data silo is stronger than the Whole Operational Digital Twin. There is lot of value in collective unified view of the asset. – Industrility Customer

The Solution: Asset-Centric App Platform by Industrility

Manufacturers know that point tools or persona-based tools exist today and does the job well. For example, Service technician uses an FSM tool to perform step by step checklist of a PM plan. But has no clue about the IoT operational data or SOP manual from the Sharepoint. To overcome the challenges posed by data and app silos, industrial organizations must embrace asset-centric app platforms. Industrility provides a unique way to visualize the operational digital twin of the asset that provides the full view of the asset to all stakeholders. These platforms provide a unified environment that breaks down silos and centralizes data from diverse sources, including machinery, sensors, document management systems, enterprise systems, and more. By this asset-centric approach, manufacturers can:

- Personalize and Customize: Every asset is unique. They run in a different environment, they are operated by different people. Asset-centric platforms enable seamless integration of data from various sources, providing a holistic view of operations. This integration enables real-time monitoring, predictive maintenance, and accurate performance analysis.

- Facilitate Collaboration: Breaking down silos fosters cross-departmental collaboration. Asset-centric platforms encourage information sharing, enabling teams to work together towards common goals and make informed decisions collectively.

- Enhance Efficiency: With a unified platform, redundant processes are eliminated, and operational efficiency is improved. Streamlined workflows, automated data collection, and enhanced communication ensure optimized resource allocation and reduced downtime.

- Drive Innovation: Asset-centric platforms unlock the power of data, empowering organizations to extract meaningful insights, identify trends across their installed base, and uncover opportunities for innovation and optimization. By leveraging machine learning and AI capabilities, businesses can enhance predictive analytics, anomaly detection, and performance forecasting.

Conclusion

The prevalence of data and app silos poses a significant challenge to the industrial market. However, organizations can break free from these limitations by embracing asset-centric app platforms like Industrility. Just as the six blind men in the story could only understand a fraction of the elephant’s true nature, businesses hindered by silos miss out on the complete picture of their operations. By adopting an asset-centric digital twin platform, manufacturers can unite their data, break down silos, and unlock the full potential of their industrial installed base. It’s time for the industrial market to embrace the power of unified platforms and steer towards a future of data-driven success.

— Jinesh