Boosting Aftermarket Revenue and Brand Reputation with QR Codes on Industrial Machinery

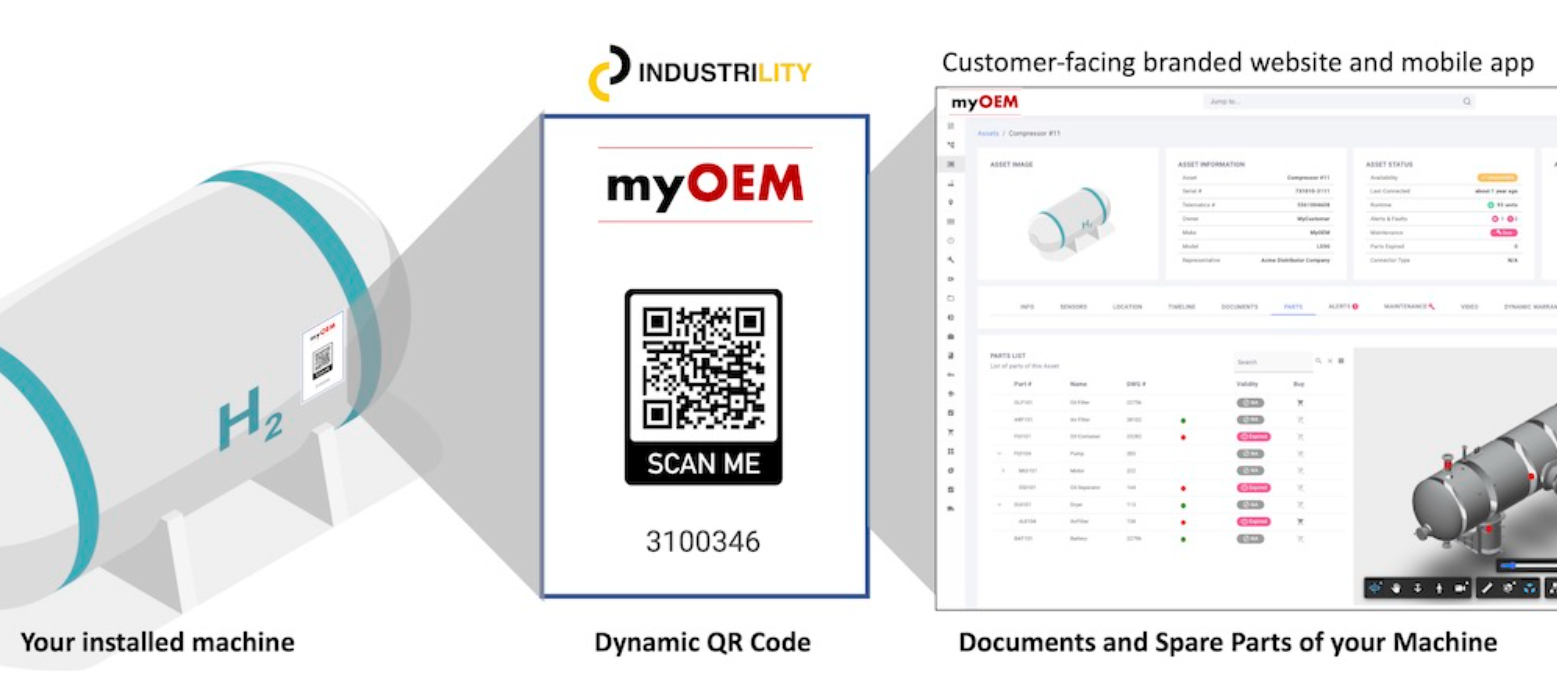

QR Codes on Industrial Machines

These small, two-dimensional codes are playing a pivotal role in improving aftermarket services and boosting aftersales revenue. In this blog, we will explore the myriad benefits of incorporating QR codes into your industrial machinery, backed by references and real-world examples.

Enhanced Equipment Maintenance and Support

One of the primary advantages of using QR codes on industrial machinery is the improved ability to perform equipment maintenance and provide timely support. By affixing QR codes to specific components or machines, technicians can easily access vital information, such as maintenance schedules, troubleshooting guides, and technical manuals.

Streamlined Equipment Registration and Warranty Tracking

QR codes simplify the process of registering industrial equipment and tracking warranties. Manufacturers can embed QR codes on the product labels, allowing customers to quickly register their purchase and access warranty information by scanning the code with a smartphone. In return the OEM captures a wealth of information like location of the assets, the contact person working on it, operating environment and machine run hours.

Hyper personalized Access to Spare Parts and Consumables

With QR codes on industrial machinery, it becomes much easier for customers to identify and order spare parts or consumables. These codes can link directly to a hyper-personalised e-commerce site, where customers can browse their equipment, check availability, and place orders. This improves order conversions and aftersales revenue by 20% and reduces support costs by 15%.

Personalized Customer Engagement

QR codes can also enable personalized customer engagement, as they can be linked to online customer portals. By scanning the code, customers can access their equipment’s history, maintenance records, and exclusive content tailored to their needs, fostering a stronger relationship between manufacturers and clients. It creates a loyalty loop with a customer and increases customer satisfaction by 15%.

Data-Driven Insights and Predictive Maintenance

QR codes can facilitate data collection and analysis, contributing to predictive maintenance strategies. By monitoring equipment usage and performance, manufacturers can proactively identify potential issues and provide maintenance services before problems escalate.

Industrilty’s after-sales app platform excels in this regard by facilitating direct communication between manufacturers and their customers. Industrility builds an often missing, special “link” between the manufacturers and customers. This link enables manufacturers to gather valuable insights about the throughout the asset’s lifecycle post-sale. Understanding the nuances of the customer’s environment allows manufacturers to design new equipment that is better suited to meet specific needs, resulting in increased customer satisfaction and loyalty.

Conclusion

Incorporating QR codes on industrial machinery is a cost-effective and versatile way to improve aftermarket services and increase aftersales revenue. The benefits include enhanced maintenance, streamlined registration and warranty tracking, access to spare parts, personalized customer engagement, and data-driven insights. As technology continues to advance, QR codes are becoming an essential tool for manufacturers and service providers looking to stay competitive in the industrial sector.

– Achint Varia