Hey manufacturers, Start Collecting Installed Base Data! Here’s How Industrility Can help?

Why does the Installed Base Data Matter?

Industrial manufacturers grapple with operational inefficiencies and strategic limitations due to a lack of comprehensive insights into their installed base data. Without a clear understanding of who their owners are, which machines they have purchased, where they are located, and how they are being utilized, manufacturers remain disconnected with their actual customers. The absence of clear information about this installed base data inhibits proactive maintenance planning, targeted marketing efforts, and optimized supply chain logistics. This data gap hinders manufacturers from delivering a seamless after-sale experience, impeding their ability to build strong customer relationships and stay competitive in the market.

The aftersales experience has become a linchpin for success. At Industrility, we believe digital aftersales programs represent an untapped frontier for building enduring customer relationships and ultimately increased aftersales recurring parts and service revenue and long-term customer loyalty.

One key question we receive from customers is “But we don’t have the installed base data”. Manufacturers either don’t have the installed base data or if they have it, it remains siloed and not accessible. In this thought leadership blog post, we’ll explore how industrial manufacturers can harness the power of a digital aftersales program to not only build their installed base data but also enhance its quality.

What is Installed Base Data:

- Equipment ID: A unique identifier for each piece of equipment.

- Serial Number: A unique serial number associated with the equipment for tracking and warranty purposes.

- Equipment Name/Model: The name or model number of the equipment.

- Description: A brief description of the equipment, including its specifications and features.

- Manufacturer: The name of the OEM that produced the equipment.

- Manufacture Date: The date when the equipment was manufactured.

- Purchase Date: The date when the equipment was sold to the distributor or end-customer.

- Customer Name: The name of the facility owner or end-customer who purchased the equipment.

- User Name: the names of the people interacting with the equipment everyday

- Customer Contact Information: Contact details for the customer, including address, phone number, and email.

- Distributor Information: Information about the distributor who sold the equipment, if applicable.

- Installation Date: The date when the equipment was installed at the customer’s site.

- Location: The physical location or site where the equipment is installed.

- Maintenance History: Records of maintenance and servicing performed on the equipment, including dates and details of maintenance activities.

- Warranty Information: Details about the equipment’s warranty, including warranty start and end dates.

- Service Contracts: Information about any service contracts or agreements associated with the equipment.

- Usage Data: Data on the usage and operational history of the equipment, such as running hours, cycles, or production data.

- Equipment Status: Current status of the equipment (e.g., operational, under maintenance, decommissioned).

- Upgrade/Modification History: Records of any upgrades or modifications made to the equipment.

- Spare Parts: Information on spare parts associated with the equipment, including part numbers and quantities and its parts sold and installed history

- Safety and Compliance Information: Documentation related to safety certifications and compliance with industry standards.

- Cost and Pricing Information: Information on the cost of the equipment and its pricing at the time of sale.

- Salesperson: The name of the salesperson or account manager responsible for the sale.

- Notes/Comments: Any additional notes or comments related to the equipment.

- Linked Documents: References or links to relevant documents, such as user manuals, technical documentation, and invoices.

- Regulations/Certification/Compliance or National Associations Identifications like ASME, NAPA etc.

How can Industrility’s Unique Platform and Technology help collect Installed Base Data?

Industrility offers a unique QR code omni-channel registration framework for manufacturers that want to collect real installed base data or have the data but would like to increase its quality. This unique QR code registration process is easy-to-use and friction-free for end-owners and dealers that collects this information at different times during the assets lifecycle and attaches it to Asset’s digital twin.

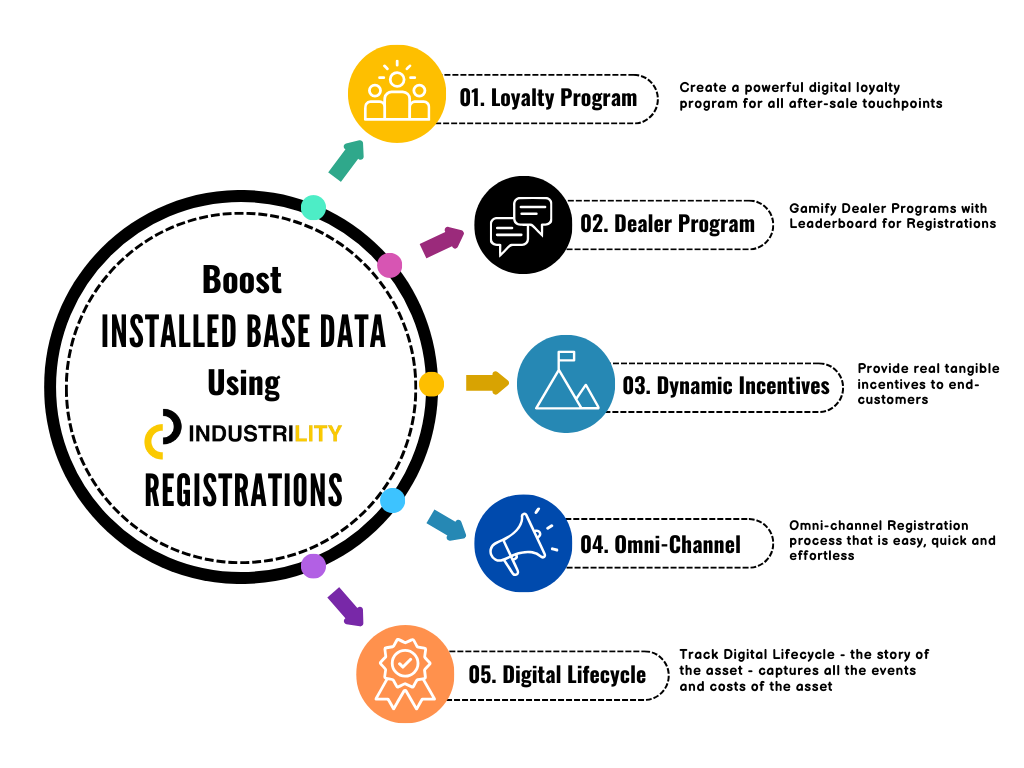

Industrility has achieved great success and increased registration rates when there is a strong partnership with Industrial manufacturers and recommends following ways to boost the installed base data.

1. Provide Incentives to End-customers/Owners via a Digital Loyalty Program: Loyalty programs that reward customers for staying connected with the manufacturer create a culture of engagement. By leveraging the data generated through these programs, manufacturers can gain insights into customer preferences, usage patterns, and equipment life cycles, contributing to a more accurate representation of their installed base. Similar to Airline Frequent Flyer Programs, Industrility makes it easy for manufacturers to launch and maintain their loyalty programs digitally. Industrility believes in providing real value back to the end-customers by creating various levels (Silver, Gold, Platinum etc.) and recommend following ideas to make the program more valuable for members:

a. Dynamic Information: All information about their assets in one place easy to access and available at their fingertips. With high attrition, physical documents, log books and manuals tend to be get lost

b. Dynamic Support: Promising personalized support to registered customers is not just about enhancing customer satisfaction; it’s about ensuring that the support team has access to the most accurate information. An integrated aftersales platform ensures that customer support teams work with up-to-date installed base data, resolving issues more efficiently.

c. Access to Exclusive Content: Granting exclusive access to advanced features or content in exchange for registration opens a two-way street of value. As customers enjoy enhanced functionalities, manufacturers gain access to a wealth of usage data that enriches their understanding of how their products are being utilized in the field.

d. Dynamic Proactive service and maintenance reminders: Industrility provides a user-friendly mobile app experience that simplifies the registration process. Integrated push notifications serve not only as reminders but also as an opportunity to gather additional data or updates on equipment status.

e. Dynamic Parts: By providing priority Access to specialized Parts pricing or even accurate availability data goes a long way to these customers.

f. Dynamic Survey: Encouraging registrations through surveys and feedback mechanisms is a direct way to gather insights. An aftersales program that seamlessly integrates this feedback loop ensures that the installed base data is not only accurate but also reflective of customer sentiments and experiences.

g. Dynamic Warranty: Industrility’s patent pending offering that calculates extended warranties using an algorithm for swiftly registered machines is more than an enticement; it’s a mechanism to encourage customers to share accurate and up-to-date information about their equipment. By leveraging this data through an intelligent aftersales program, manufacturers can establish a solid foundation for improving the overall quality of their installed base data.

h. Dynamic Discounts: Providing discounts on accessories, spare parts, or upgrades upon registration is not just a sales strategy; it’s a means to incentivize customers to update their machine details. Through an integrated aftersales program, manufacturers can seamlessly capture this data and ensure the accuracy of their installed base records.

i. Go Carbon Neutral: Unlock new data which manufacturers would not typically get by tying registrations to environmental initiatives. Through an aftersales program, manufacturers can gather data on the lifecycle of their products, enabling them to make informed decisions for more sustainable and eco-friendly manufacturing practices.

2. Provide Incentives to Dealers/Distributors

Whether you call Dealers, Distributors, Reps, Partners, Packagers or contractors, if they own the relationship with end-customers, Industrility believes in providing dynamic and tangible incentives for accurate and product registrations and re-registration data.

a. Dynamic Rebates for Accurate Registrations: Industrility tracks registrations and calculates accurate actual rebates the dealers should get at the end of the year. This is calculated programmatically using an AI algorithm that calculates “Dealer Score”

b. Gamification: Gamifying the registration process turns a routine task into an engaging experience. Engage competing distributors with leaderboard does wonders. The data generated through gamification provides manufacturers with insights into user behaviors, preferences, and equipment specifications, contributing to a more refined installed base dataset.

c. Hero Program: Publicly recognizing and celebrating registered customers through an aftersales program not only builds brand loyalty but also contributes to the authenticity of installed base data. Highlighting real stories provides manufacturers with tangible data points about how their products are making a positive impact in the field.

d. Drive Campaigns and Contests: Running contests and giveaways exclusively for registered customers not only fosters a sense of community but also generates valuable data. An aftersales program that integrates these activities can turn customer engagement into a goldmine of insights, refining the installed base data with each interaction.

e. Dynamic Inspections and Walkthroughs: Using Industrility’s Walkthrough app, Dealers can quickly execute a fool-proof inspection at the customer site and capture all the necessary data related to assets at a site or a building. These free walkthroughs, certified by the manufacturers could be great lead generation or optimization activities for replacement, repair or upgrades for Dealers and great detailed report for end-customers. Routine free inspections can also increase quality of the Installed Base Data.

3. Consolidate Installed Base Transactions with Asset Authchecks

Similar to Credit Bureaus and Credit Card Authorizations, Industrility provides Asset Auth Checks that validates and authenticates an active asset using event and cost pulses. Industrility knows that Industrial Manufacturers’ Installed Base data is messy, fragmented and difficult to access. Bits and pieces of Installed Base data exist in CRM, Warranty Management Systems, Service Software, Dealer Management Systems, ERPs and so on. This transaction system act as a central hub for Installed Base and provides the latest status of an active asset when event or cost pulse data is available.

a. Asset’s Timeline: These systems can connect and send an event pulse related to Asset Serial # to Industrility Timeline app which tracks these diverse chronological events across various disparate systems. By centrally tracking these events, Industrility can tell a story of Asset’s lifetime through events.

b. Asset’s Lifecycle Costs: The disparate financial systems can send a cost pulse to the same transaction system to track lifecycle costs. From commissioning to maintenance, to repair and decommissioning, Industrility scalable transaction system can track costs of a given asset.

Industrilty’s after-sales app platform enables equipment manufacturers to collect installed base data from the field using its unique QR-code Omni-channel Registration Framework

Conclusion

In conclusion, a strategic digital after-sales program is not just about post-purchase support; it’s a dynamic avenue for data enhancement. By weaving these three programs into their after-sales strategy, industrial manufacturers can not only drive customer loyalty but also elevate the quality of their installed base data to new heights. It’s a holistic approach that aligns customer satisfaction with operational excellence, paving the way for a future -where manufacturer remain always connected to their customers.

— Jinesh Varia