The Pragmatic Manufacturer’s Guide to Servitization: Profits Beyond the Sale

Servitization: From Product Centric To Service Centric

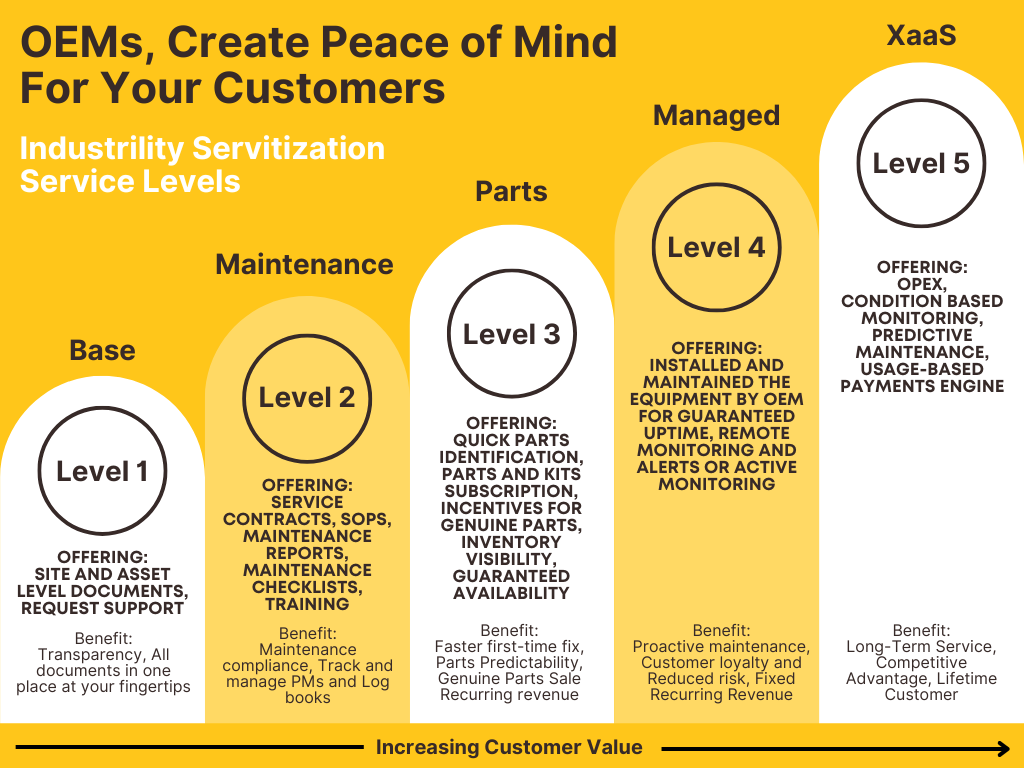

Manufacturers constantly refine their service offerings, develop new revenue models (e.g., pay-per-use), and optimize product design based on real-world usage data through servitization. But, what exactly is servitization, and how can manufacturers ascend this ladder to success? In this blog, we’ll go through the steps involved in building a robust servitization strategy, exploring the abundant benefits it offers, and navigating the potential challenges that may arise. We’ll also shed light on how to measure success through key metrics and ROI and how Industrility can be a help.

Pragmatic steps to consider while enabling Digital Servitization

Here are the steps that organizations can follow to climb the servitization ladder using installed base and asset data effectively:

- Building a connection: Offer your customers personalized information for their equipment like manuals, spare-parts, pre-active service reminders and warranty incentives so that customers are more connected with you.

- Data Collection and Integration: Start by collecting and integrating data from installed bases and assets. This includes sensor data, historical maintenance records, customer feedback, and other relevant information.

- Data Analysis: Employ advanced analytics and machine learning to extract meaningful insights from the collected data. Identify patterns, trends, and opportunities for improving service delivery.

- Predictive Maintenance: Use predictive analytics to anticipate maintenance needs and intervene proactively. This reduces downtime, improves customer satisfaction, and can be a valuable upselling opportunity.

- Customization: Tailor your services to meet the specific needs of individual customers. Utilize installed base data to understand your clients better and offer solutions that address their unique challenges.

- Performance Metrics: Establish key performance indicators (KPIs) based on asset data to monitor and report on the performance of your products or equipment. This forms the basis for performance-based contracts.

- Continuous Improvement: Regularly review asset data to identify areas for product improvement. Use this feedback to enhance product design, durability, and efficiency.

- Feedback Loop: Maintain a strong feedback loop with customers. Gather their input, assess their satisfaction, and use their feedback to refine your services continually.

Benefits of Servitization:

Climbing the servitization ladder using installed base and asset data offers numerous benefits for both manufacturers and customers:

- Steady Revenue Streams: By offering services alongside products, companies can establish consistent and recurring revenue streams.

- Enhanced Customer Relationships: Servitization fosters stronger, longer-lasting relationships with customers by providing ongoing value and support.

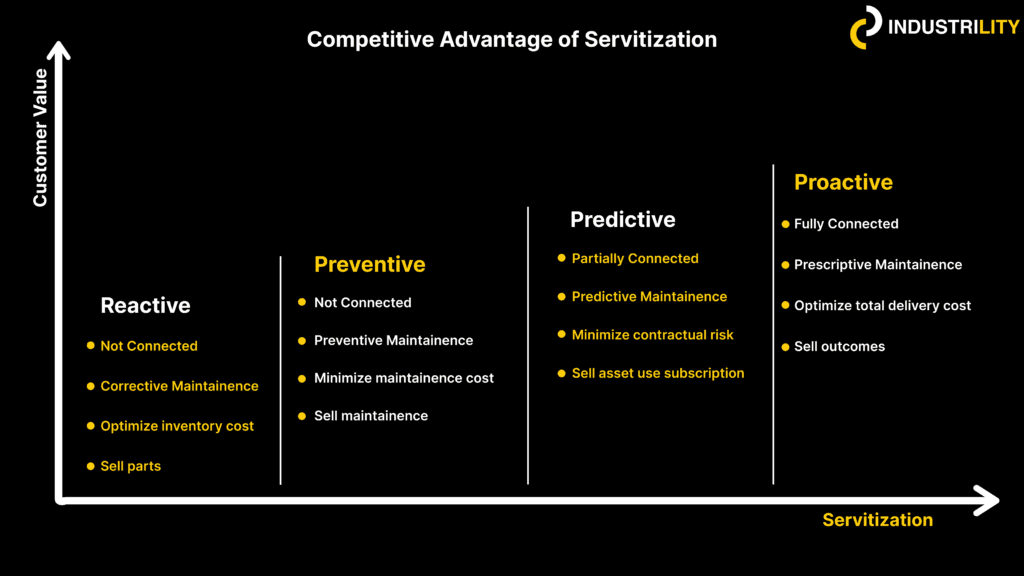

- Competitive Advantage: Focusing on services differentiates a company from competitors who solely offer products.

- Cost Efficiency: Predictive maintenance and data-driven decision-making lead to cost savings in the long run.

- Innovation and Differentiation: Asset data can be a valuable source of information for product innovation and differentiation.

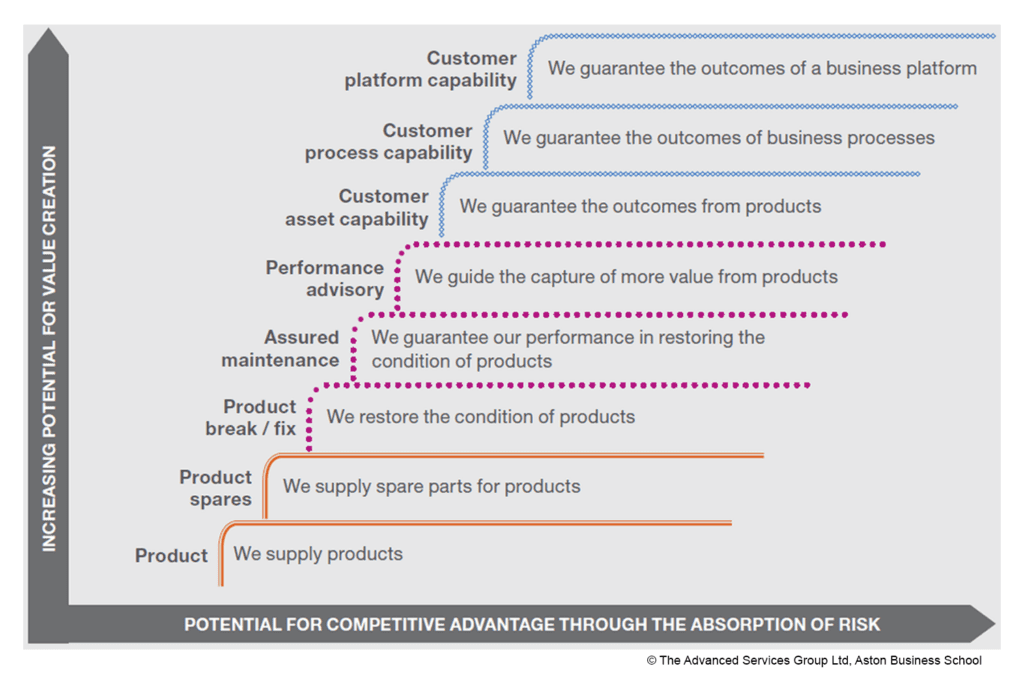

Profitability and Competitive Advantage

Profitability takes center stage with servitization. Recurring service contracts provide a predictable and reliable income source, unlike the volatile nature of one-time product sales. This financial stability empowers manufacturers to invest in advanced analytics capabilities, further optimizing service delivery and boosting margins.

But the true power of servitization lies in its ability to cultivate deep customer intimacy. By analyzing data gleaned from sensor-embedded equipment and service interactions, manufacturers gain a 100% knowledge advantage on asset performance, customer usage patterns, and evolving needs. This knowledge translates to:

- Predictive maintenance: Anticipating and preventing equipment failures minimizes downtime, a major cost driver for manufacturers.

- Personalized service packages: Tailored service offerings that address specific customer needs not only enhance customer satisfaction but also open doors to upselling and cross-selling opportunities for high-value services.

- Outcome-based contracts: Customers pay based on achieved results (e.g., uptime guarantees, energy savings), aligning incentives and fostering trust.

Competitive advantage takes on a whole new meaning. With servitization, manufacturers transform from mere product vendors to trusted advisors and partners. By offering a holistic solution that encompasses the equipment, expertise, and ongoing support, they differentiate themselves from the competition solely focused on product transactions. Furthermore, the knowledge advantage gained through servitization fuels continuous innovation.

This isn’t just about selling a machine; it’s about selling a promise. A promise of optimized performance, reduced costs, and a smooth operational experience for the customer.

Challenges of Servitization

The road to servitization is not without its challenges. Just like navigating uncharted territory, it requires a clear understanding of the potential hurdles and a strategic plan to overcome them:

- Shifting Mindsets: The biggest challenge lies in a fundamental shift in mindset. Transitioning from a product-centric model to a service-centric one requires a cultural transformation within the organization. Sales teams need to adapt from one-off transactions to building long-term customer relationships. Similarly, engineering teams need to move beyond product design to consider the entire lifecycle of the equipment and design for optimal serviceability.

- Internal Integration: Breaking down silos between departments is crucial for successful servitization. Sales, engineering, service, and data analytics teams need to work in close collaboration. Information sharing and seamless communication are vital to ensure a unified customer experience and optimize service delivery.

- Capability Gaps: Servitization often exposes gaps in existing capabilities. Manufacturers may need to invest in new skills and expertise, such as data analysis, remote monitoring, and advanced maintenance techniques. Additionally, building a robust IT infrastructure to support service delivery and data management is often necessary.

- Upfront Investment: The transition to servitization requires upfront investment in technology, training, and potentially new service personnel. This can be a significant hurdle, especially for smaller manufacturers with limited resources. However, a long-term perspective is crucial. These investments can be viewed as seeds sown, promising bountiful harvests in the form of recurring revenue streams and increased customer loyalty.

- Data Security Concerns: The success of servitization hinges on collecting and analyzing data from connected equipment. However, this raises concerns about data security and customer privacy. Manufacturers need to implement robust cybersecurity measures and ensure transparent data practices to build trust with customers.

- Customer Buy-In: Not all customers are immediately receptive to the servitization model. They may be hesitant to embrace new pricing structures or unfamiliar service contracts. Manufacturers need to communicate the value proposition of servitization, highlighting the benefits of optimized performance, reduced downtime, and lower total cost of ownership.

The challenges of servitization are real, but they are not insurmountable. By proactively addressing these concerns, investing in the right capabilities, and creating a culture of collaboration, manufacturers can transform these hurdles into stepping stones on their journey towards a future fueled by servitization.

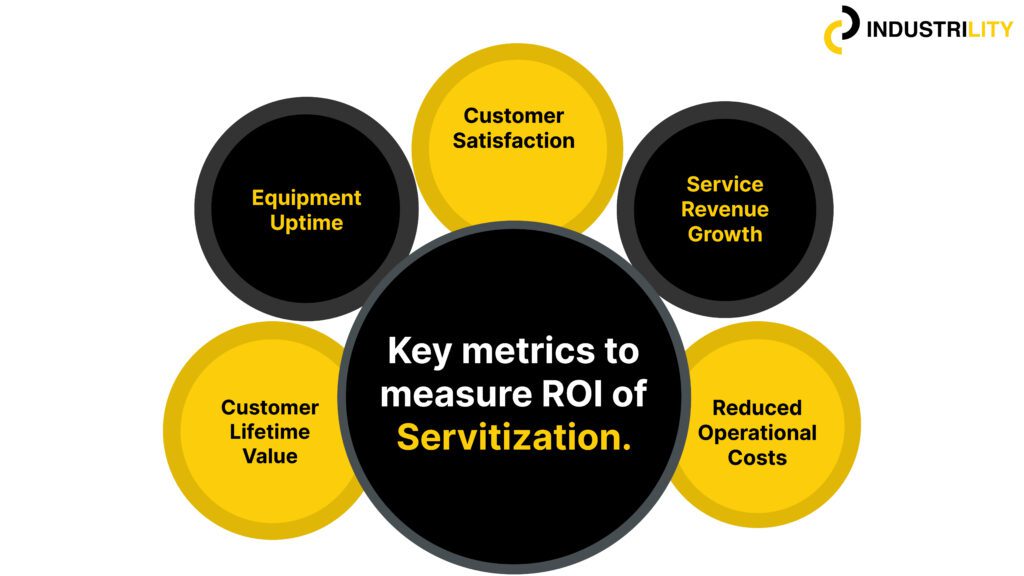

Metrics and ROI

Servitization promises a wealth of benefits for manufacturers. But how do we quantify these benefits and demonstrate the true Return on Investment (ROI)? Here are some key metrics that illuminate the path to success:

- Customer Lifetime Value (CLTV): This metric goes beyond the initial product sale, focusing on the total revenue a customer generates over their entire relationship with the manufacturer. Servitization fosters stronger customer relationships, leading to increased CLTV through recurring service contracts, upselling opportunities, and repeat business.

- Equipment Uptime: Downtime translates to lost productivity and revenue. By employing predictive maintenance enabled by servitization data, manufacturers can significantly improve equipment uptime, directly impacting their bottom line.

- Customer Satisfaction: Happy customers are loyal customers. Metrics like Net Promoter Score (NPS) and Customer Satisfaction (CSAT) surveys track customer sentiment regarding service offerings. High satisfaction translates to stronger brand loyalty and increased customer lifetime value.

- Service Revenue Growth: Servitization opens doors to new revenue streams beyond the initial product sale. Tracking service revenue growth helps assess the effectiveness of service offerings and identify areas for further development.

- Reduced Operational Costs: Predictive maintenance minimizes unnecessary repairs and downtime. Additionally, data-driven insights on equipment performance can inform design improvements, leading to more efficient and cost-effective products in the long run.

Measuring the ROI of Servitization requires a holistic approach, considering both financial and non-financial benefits. Here’s where the aforementioned metrics come into play. By analyzing changes in CLTV, equipment uptime, customer satisfaction, service revenue growth, and operational cost reduction, manufacturers can calculate the tangible financial gains associated with servitization.

However, the impact extends beyond just the bottom line. The intangible benefits of servitization, such as improved brand reputation, stronger customer relationships, and a competitive edge through continuous innovation, are equally valuable. While these factors might be more challenging to quantify directly, their long-term impact on a manufacturer’s success can be immense.

Industrilty’s digital servitization app platform and consulting services enables equipment manufacturers to launch, manage and scale their servitization and business model innovation without a big, complex and long IT project.

Conclusion

Industrility understands the power of servitization and is here to help you accelerate your journey. Our comprehensive suite of solutions empowers you to get started quickly, demonstrate value rapidly, and effortlessly capture valuable data from your installed base. We recognize that every manufacturer’s servitization journey is unique. Industrility provides a streamlined onboarding process, minimizing disruption to your current operations. This allows you to pilot servitization initiatives swiftly, enabling you to demonstrate the tangible benefits to both your organization and your customers. Partner with us today and we’ll equip you with the tools and expertise necessary to navigate this exciting transformation, ensuring you reap the rewards of a customer-centric, data-driven future.

– Achint Varia