- Industrility

- Blog

Step Back in Time Explore Our Blog's Fascinating Archive!

Category

Regulatory Trends and the role of Digitalization and AI

New regulations in Europe and the U.S. are reshaping aftersales for OEMs, emphasizing repairability, sustainability, and data transparency. Compliance challenges also bring opportunities—AI, digital twins, and smart parts identification can drive efficiency, customer engagement, and competitive advantage. OEMs that embrace digitalization will turn regulatory shifts into growth and innovation.

AI Agents in 2025 is transforming Aftersales

Discover how AI Agents are transforming Customer Experience for machinery manufacturers, boosting efficiency, reducing downtime, and increasing revenue through automation and predictive maintenance.

The Dreaded Job Folder: The Manufacturer’s Real Villain

For as long as anyone can remember, manufacturers have struggled with the ‘Dreaded Job Folder’—a chaotic catch-all for every piece of data related to a job or machine, often buried in a shared network drive. Industrility offers a way out, transforming this outdated practice with a modern aftersales platform that organizes, digitizes, and streamlines access to critical information. Discover how Industrility’s solution helps manufacturers reclaim time, boost efficiency, and elevate customer service.

Part 1: The IoT Revolution in After Sales for Industrial Manufacturers

The article explores how Industrility is transforming industrial B2B ecommerce and machinery sales enabled with AR(Augmented Reality)/VR (Virtual Reality). This innovation improves buying experience, accurate parts identification, reduction in returns and ultimately higher uptime and improved customer loyalty.

The future of industrial e-commerce with 3D visualization using AR and VR

The article explores how Industrility is transforming industrial B2B ecommerce and machinery sales enabled with AR(Augmented Reality)/VR (Virtual Reality). This innovation improves buying experience, accurate parts identification, reduction in returns and ultimately higher uptime and improved customer loyalty.

How AI-Powered Aftersales is Revolutionizing CNC Machining

The article explores how Industrility is transforming industrial maintenance by integrating AI-powered “digital coworkers” to assist service technicians. These AI agents enhance efficiency during installation, maintenance, and upgrades, ensuring accurate, real-time support. This innovation reduces machine downtime and improves operational excellence in the industrial sector.

The Future of Machine Uptime: AI-Powered Teammates for Service Technicians

The article explores how Industrility is transforming industrial maintenance by integrating AI-powered “digital coworkers” to assist service technicians. These AI agents enhance efficiency during installation, maintenance, and upgrades, ensuring accurate, real-time support. This innovation reduces machine downtime and improves operational excellence in the industrial sector.

Transforming O&M Manuals with GenAI: The Future of Machinery and Equipment Maintenance

Industrility’s TwinGPT revolutionizes Operations and Maintenance (O&M) manuals by integrating GenAI technology. It transforms static manuals into interactive, personalized experiences, enhancing efficiency and first-time fix rates. This innovative solution bridges the skills gap and simplifies onboarding, setting a new standard for machinery maintenance in the industry.

Industrility Launches TwinGPT on AWS Marketplace

Industrility has launched its innovative TwinGPT offering on AWS Marketplace, enhancing heavy machinery manufacturing with advanced AI capabilities. This integration ensures scalability, security, and efficiency, enabling users to create digital twins, predict maintenance needs, and make data-driven decisions, all within a trusted AWS environment.

Why Predictive Maintenance is a Must-Have for OEMs

The article emphasizes Industrility’s role in promoting predictive maintenance for OEMs using IIoT technology. It illustrates how this approach prevents equipment failures, enhances customer satisfaction, and boosts revenue through service contracts. By adopting predictive maintenance, OEMs can transform operations and provide exceptional customer service, avoiding costly downtime.

Industrial Metaverse and Aftersales

The article explores how Industrility leverages the industrial metaverse to enhance aftersales services. Key benefits include improved training through AR/VR, predictive maintenance with digital twins, interactive customer engagement, streamlined spare parts management, and cost reductions, ultimately driving customer satisfaction and operational efficiency.

The Industrial Metaverse: Transforming the Future of Manufacturing

The article discusses how Industrility is revolutionizing manufacturing through AI-powered “digital coworkers” that assist service technicians, enhancing efficiency and reducing machine downtime. It also highlights Industrility’s TwinGPT, which transforms static O&M manuals into interactive experiences, bridging the skills gap and setting new industry standards.

Making Effective Digital Twins a Reality for Your Industrial IoT Strategy

The article highlights Industrility’s innovative use of digital twins and AI to improve industrial maintenance. It discusses AI-powered assistants for technicians, interactive O&M manuals, and the importance of predictive maintenance, all aimed at enhancing efficiency, minimizing downtime, and boosting customer satisfaction in the industrial sector.

The CSRD Regulation: Challenges and Opportunities for Manufacturers and Machinery Makers

The article discusses the CSRD regulation’s impact on manufacturers, emphasizing the challenges of compliance and the opportunities for innovation. It highlights Industrility’s role in transforming industrial maintenance through AI-powered solutions and predictive maintenance, enhancing efficiency, reducing downtime, and promoting sustainability in the manufacturing sector.

Carbon Footprint Reduction Made Easy

Industrility’s Decarbonize app helps manufacturers reduce carbon emissions by monitoring energy consumption, identifying inefficiencies, and enhancing machine performance. By integrating IoT and analytics, it provides real-time insights, supports predictive maintenance, and promotes sustainability. The app also assists in selling eco-friendly upgrades and services, driving both efficiency and sustainability goals.

Revolutionizing Sustainability in Manufacturing: AI’s Impact on Industrial machinery

The article highlights Industrility’s role in enhancing sustainability in manufacturing through AI-driven boiler efficiency optimization. By integrating IIoT and AI, Industrility helps reduce energy consumption, improve reliability, and streamline maintenance, enabling manufacturers to achieve significant cost savings while contributing to a greener future.

5 Benefits of Exploded Machinery Views: How Machine Manufacturers Can Improve Customer Experiences Easily

Industrility highlights five benefits of exploded machinery views for OEMs: improved maintenance efficiency, accurate parts identification, streamlined training, enhanced customer support, and innovation in product development. These views allow manufacturers to visualize machine components clearly, boosting operational efficiency, reducing costs, and improving customer experience.

Industrility Achieves SOC 2 Type II Certification, Reaffirming Commitment to Data Security Excellence

Industrility has achieved the SOC 2 Type II certification, highlighting its commitment to data security, privacy, and operational integrity. This certification assures clients that Industrility’s systems meet the stringent standards for safeguarding data and maintaining system availability, making it a trusted partner for industrial machinery manufacturers.

Unleashing the Power of Installed Base Data: Industrility’s Solution to True Total Cost of Ownership

Industrility’s blog explains the importance of understanding Total Cost of Ownership (TCO) and Lifecycle Costs (LCC) for industrial equipment. The company’s Lifecycle app tracks data on equipment costs across its lifecycle, offering businesses insights to optimize maintenance, minimize downtime, and make informed purchasing decisions. Industrility’s AI-powered platform also supports predictive maintenance, helping manufacturers and owners enhance efficiency and reduce operational costs.

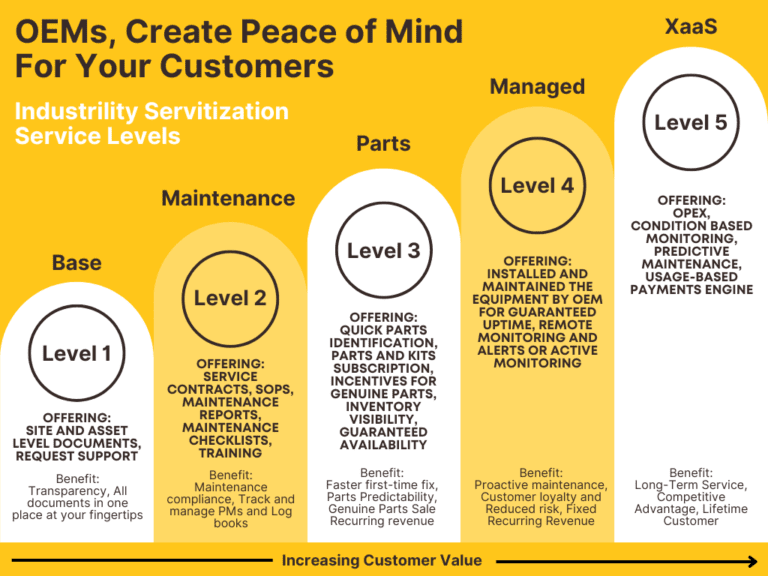

The Pragmatic Manufacturer’s Guide to Servitization: Profits Beyond the Sale

Pragmatic guide for manufacturers to embrace digital servitization, a business model focused on delivering value through services alongside products. Their solutions empower businesses to get started quickly, capture data from their installed base, and demonstrate value to customers. Navigate this transformation and reap the rewards of a customer-centric future.

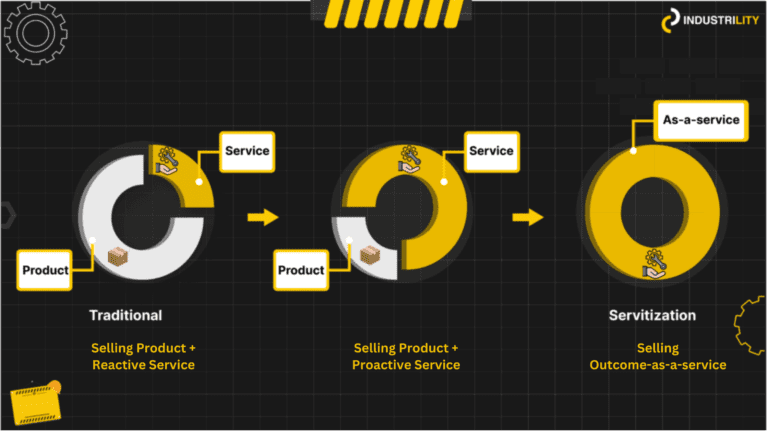

Servitization: The Business Buzzword Explained (and Why You Should Care)

Companies are going beyond simply selling products. They’re looking to create lasting relationships with customers by offering services that complement their physical offerings. This is where digital Servitization comes in. Think of it as the marriage of two powerful trends: the shift from product-centric to service-centric business models, and the ever-growing influence of digital technologies.

6 Trends Revolutionizing After-Sales Revenue

In the aftersales goldmine, Manufacturers need to know where to dig (Know their Installed base), how much to dig (use data to drive value added services to the customers) and dig efficiently (focus on faster time to market with scaling cost effectively as they grow).

From Machines to Smart Systems: The IoT Revolution in Manufacturing in 2024

A system of industry machinery speaking to each other and reporting in crucial data figures could impact, TCO, longevity, output and even massive savings. Embrace the data deluge – implement IoT across your heavy machinery.

Embrace Collaboration: How leaders in equipment manufacturing companies can think about adopting new technology

The key to success in this evolving landscape is a strategic shift towards collaboration and partnerships to deliver innovative software solutions. Don’t ignore the true cost of changing your Engineering DNA.

Hey manufacturers, Start Collecting Installed Base Data! Here’s How Industrility Can help?

Manufacturers either don’t have the installed base data or if they have it, it is siloed and not accessible. In this thought leadership blog post, we’ll explore how industrial manufacturers can harness the power of a digital after-sales program to not only build their installed base data but also enhance its quality.

Aftersales Mastery: Love a winning strategy for Equipment Manufacturers

In the aftersales goldmine, Manufacturers need to know where to dig (Know their Installed base), how much to dig (use data to drive value added services to the customers) and dig efficiently (focus on faster time to market with scaling cost effectively as they grow).

Service Deficiency: The Untold Impact of Neglected Aftersales Support in Industrial Landscapes

The negative impact of a lack of aftersales support in industrial companies is far-reaching, affecting customer relationships, brand perception, and financial performance. Companies that neglect the importance of post-sale support risk losing competitive advantages and jeopardizing their long-term sustainability in the market.

Boosting Aftermarket Revenue and Brand Reputation with QR Codes on Industrial Machinery

The benefits include enhanced maintenance, streamlined registration and warranty tracking, access to spare parts, personalized customer engagement, and data-driven insights.

Overcoming the Fears of Scaling Aftermarket Services

If you split the revenue of any manufacturer into new equipment sales

Transforming After-sales: The Crucial Role of Digitally Enabled Asset Lifecycle Solutions

Original Equipment Manufacturer Give this Message to Your Customers “We pledge our

How can Digital-First Aftersales Platform Help Increase Revenue, Customer Loyalty, and Profitability?

In the ever-evolving landscape of business, staying ahead means capitalizing on untapped

The Power of Service and Data: Building a Lifetime Customer Loyalty Loop with Asset Owners

In the competitive landscape of industrial manufacturing, machine manufacturers strive to establish

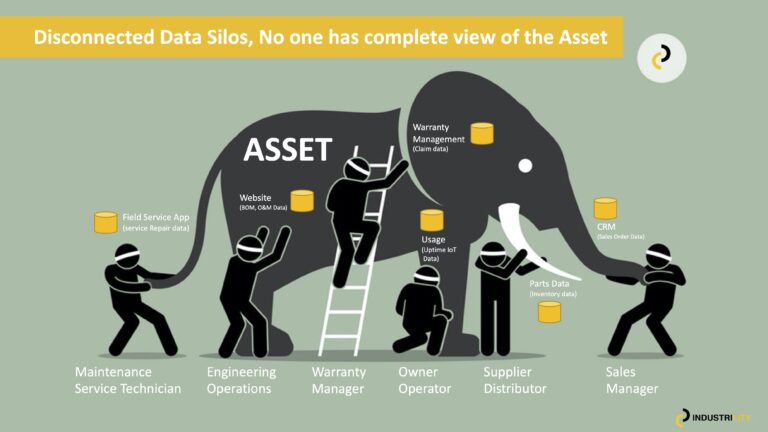

Unleashing Industrial Manufacturers from the Grip of Data Silos: The Asset-Centric Revolution

In every industry, including Industrial Manufacturing, data is the lifeblood that fuels

Five Reasons Why Manufacturers Need a Customer-facing After-sales Portal Today

In today's competitive business environment, Industrial OEMs are under constant pressure to