Revolutionizing Sustainability in Manufacturing: AI’s Impact on Industrial machinery

In the realm of manufacturing, sustainability has become a critical focus, driven by the need to reduce environmental impact and cut costs. By 2050, carbon dioxide removal could be a $1.2 trillion dollar industry. However, a new era has dawned with the integration of IIoT (Industrial Internet of Things) and Artificial Intelligence (AI) into energy consuming machinery operations, promising not just sustainability but also massive financial savings.

The Need for Sustainable Machinery:

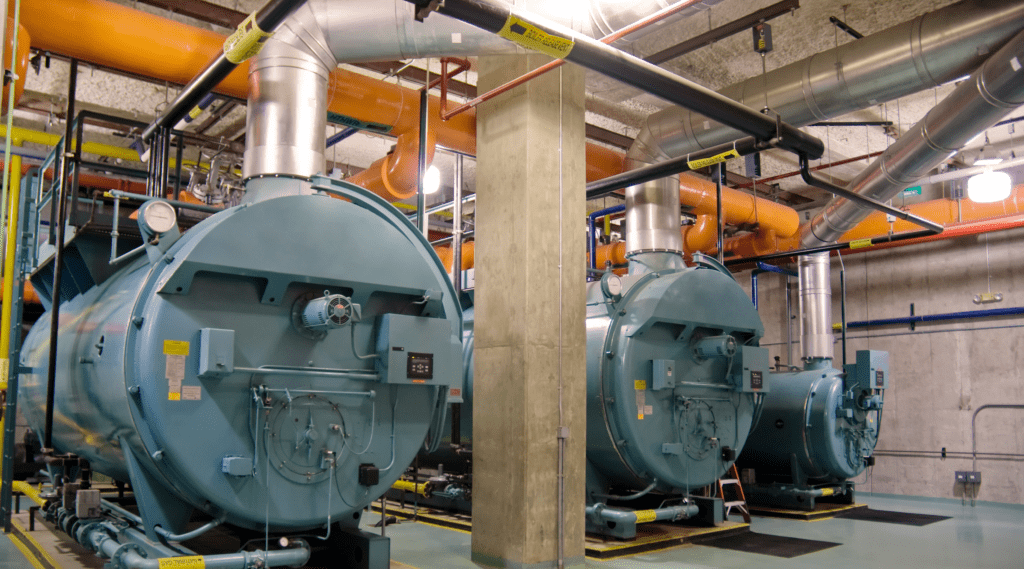

Industrial boilers are among the largest consumers of energy in manufacturing plants, accounting for up to 60% of total energy consumption. Studies have shown that the commercial boilers are inefficiently sizes, operated, maintained and run to the tune of 35%. This inefficiency not only translates into significant financial losses but also contributes significantly to carbon emissions. As the world shifts towards sustainability, industries are under pressure to adopt eco-friendly practices and technologies.

AI-Driven Solutions: A Game-Changer in Boiler Efficiency

Recent advancements in AI have revolutionized the optimization of industrial boilers. AI algorithms can analyze vast amounts of data to identify inefficiencies and recommend corrective actions, leading to substantial improvements in boiler efficiency.

By leveraging advanced algorithms, vast IIoT and sensor data; monitoring the energy consumption, identifying inefficiencies and recommending precise corrective actions is now possible. This technology can boost boiler efficiency by up to 15%, translating to annual savings exceeding $250,000 through reduced boiler trips, fuel conservation and extended boiler lifetime. By pro-actively monitoring various parameters of the boilers like: fuel flow, burner pressure, steam temperature, emissions of O₂, CO, NOx, SO₂, air flow and others, the boiler observability engine can trigger alerts, suggest optimization strategies to enhances fuel consumption and reduces emissions, with some implementations achieving a 5% reduction in fuel use and a 10% decrease in emissions. This not only cuts costs but also supports sustainability efforts, making AI a pivotal player in modern manufacturing.

AI-Driven Boiler Efficiency Optimization

AI-driven boiler efficiency optimization is a cutting-edge technology that leverages artificial intelligence (AI) and machine learning (ML) algorithms to enhance the performance and efficiency of boilers. By analyzing historical data, real-time sensor measurements, and operational parameters, AI-driven boiler optimization systems offer several key benefits and applications for businesses:

- Reduced Energy Consumption: First step to reducing energy consumption is energy monitoring. IIoT and AI can continuously monitor the boilers to show trends and changes in boiler operations compared to other boilers thereby helping decision making for optimization. e.g. Data showed that the boiler was working continuously even on weekends when the factory was only working 5 days a week

- Improved Boiler Reliability: AI analyzes sensor data and historical performance to detect and predict potential problems, enabling proactive maintenance and extending boiler lifespan.

- Enhanced Safety: Real-time monitoring of critical safety parameters like pressure, temperature, and flame stability helps identify potential hazards for immediate action.

- Optimized Maintenance Scheduling: Over maintenance or under maintenance can significantly impact the performance of the equipment and result in waste. Condition based monitoring with AI on IIoT data is used to predict maintenance needs based on usage and historical records, minimizing downtime and maintenance costs.

- Compliance and Reporting: Automated reports on boiler performance and regulatory compliance simplify tracking environmental sustainability efforts.

Conclusion

As industries strive to become more sustainable, solutions like Industrility’s modular offering can play a crucial role. Industrility’s platform enables manufacturers to digitize their operations, optimize machinery efficiency, and reduce environmental impact. Industries can not only achieve significant cost savings but also contribute to a greener future. Embracing sustainability through AI-driven solutions is not just a choice but a necessity for the future of manufacturing.