Embrace Collaboration: How leaders in equipment manufacturing companies can think about adopting new technology

Build vs Partner vs Buy : Demystifying industrial manufacturers dilemma

In an era dominated by digital transformation, equipment manufacturing companies are realizing the undeniable importance of incorporating software solutions into their offerings to their customers. Especially with the advent of IoT, AI,/ML, Generative AI, LLM, digital-twin, AR/VR and the other buzz words coming at an ever increasing pace, the owner/operator is expecting a superior offering – FAST. However, the challenge lies in differentiating between core competencies and non-differentiating solutions. Many companies find themselves at a crossroads, contemplating whether to divert resources into building software capabilities (thereby diluting their DNA) or to stay focused on their core manufacturing expertise.

The biggest challenge is the mindset and ego of manufacturers: “My business is unique, and I am going to build everything in-house”

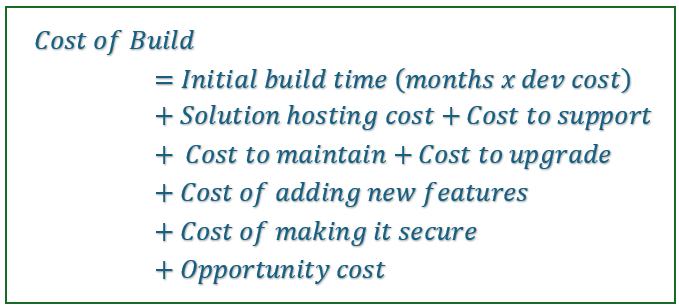

What are the real costs?

The key to success in this evolving landscape is a strategic shift towards collaboration and partnerships to deliver innovative software solutions. While it may be tempting for equipment manufacturers to venture into software development, it is crucial to recognize that not all solutions contribute to a unique market position. For example: Diverting resources to build an IT infrastructure, develop a security model, building data models, coding applications, building a user-interface and design, getting the equipment connected and analysing data, hiring and retaining a team of different software skill set are all non-differentiating capabilities can divert resources and attention away from the core business.

The benefits of collaboration extend beyond avoiding resource diversion:

- Modern technology stack: It provides equipment manufacturers with access to cutting-edge technologies. They also ensure future compatibility and faster alignment with current market trends

- Faster time-to-market: Specialized solution companies bring a wealth of experience and industry knowledge to the table, ensuring that the solutions are not only functional but also aligned with market needs and are ready to be customized and deployed.

- Outside-in Innovation: Collaboration fosters a culture of innovation within the organization. By working alongside software experts, equipment manufacturers can infuse their products with advanced features and functionalities, enhancing overall competitiveness. The exchange of ideas between different domains often sparks creativity and propels both partners towards ground breaking solutions. It enabled manufacturers offer a more iterative market offering which is an alien concept for machine builders focused on perfection and a complete product.

- Staying agile, staying current: In a rapidly evolving technological landscape, staying nimble is a competitive advantage. Collaborative efforts allow equipment manufacturers to adapt swiftly to changing market demands and technological advancements. This agility ensures that companies remain at the forefront of innovation without spreading themselves thin by attempting to do everything in-house.

- Opportunity cost: Time, talent and investment are at an utmost premium in this rapidly changing environment. Investing in building software WILL come at a trade-off of focusing on the core-competency of excelling in equipment manufacturing. Allocating management task at collaborating with software companies will free-up more engineering time to focus on your main product, which will reduce the risk of opportunity costs.

The success stories of collaborative ventures in various industries highlight the potential benefits of this approach

- Starbucks and Spotify: Recognizing the growing demand for personalized music experiences, Starbucks partnered with Spotify to create a unique in-store music streaming service. By leveraging Spotify’s vast music library and expertise in music curation, Starbucks was able to enhance the overall customer experience, creating a more engaging and memorable ambiance within their stores. This partnership not only increased foot traffic but also boosted customer loyalty and retention

- Collaboration between Coca-Cola and McDonald: With Coca-Cola being the exclusive beverage provider for McDonald’s restaurants worldwide. This partnership has not only solidified Coca-Cola’s market dominance but also ensured a consistent and high-quality beverage offering for McDonald’s customers globally

- Rolls-Royce and Microsoft: A striking example of an industrial company innovating through collaboration instead of in-house development is Rolls-Royce. Recognizing the limitations of their internal solutions, Rolls-Royce collaborated with Microsoft Azure. By leveraging Azure’s cloud computing and machine learning capabilities, they built the IntelligentEngine Results: Improved customer experience, Improved engine performance and reduced maintenance cost.

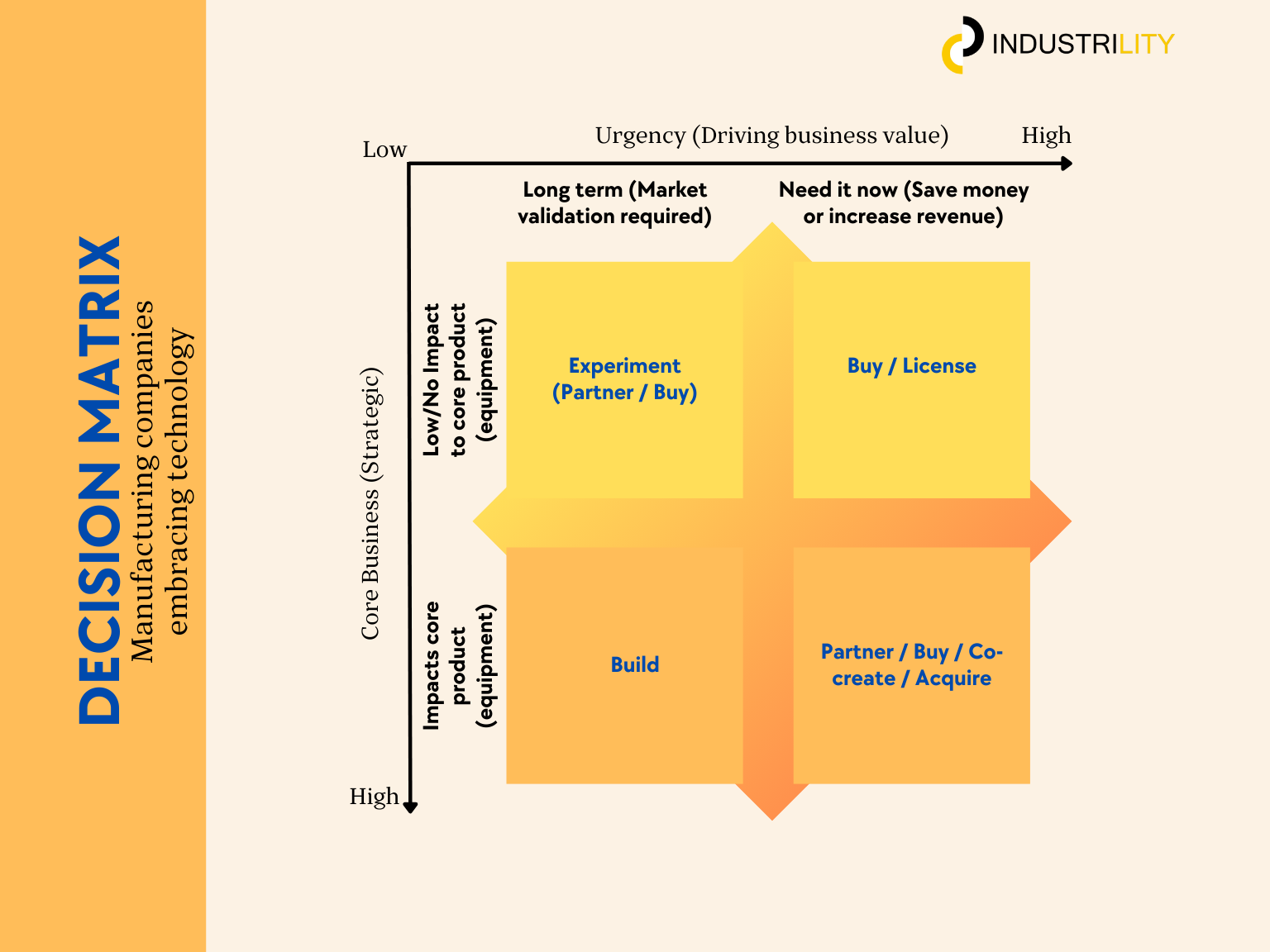

Build vs Buy decision matrix for OEMs investing in Software

A simple decision making matrix which will help you decide between build vs partner vs buy.

Industrilty’s after-sales app platform and consulting services enables equipment manufacturers to launch, manage and scale their aftersales function, build a special customer link building a customer intimacy, improving superior customer satisfaction, better brand reputation; All of this without being a big and long IT project.

Conclusion

The journey towards incorporating software solutions into equipment manufacturing is a strategic decision that demands careful consideration. Instead of attempting to become software developers in isolation, the key lies in collaboration. By forging partnerships with specialized software development firms, equipment manufacturers can unlock the full potential of digital transformation while maintaining a steadfast focus on their core competencies. This collaborative approach not only ensures the delivery of high-quality solutions but also propels companies towards sustained success in a rapidly evolving business landscape.

– Achint Varia